Three-dimensional (3D) printing is revealing its potential in the pharmaceutical industry as it turns personalised medicine into reality. In fact, additive manufacturing has the unique ability to deliver quickly, flexibly and economically set amounts of patient-specific drugs with bespoke properties, such as formulations, dosages or geometries. To achieve that and meet strict regulatory requirements, the […]

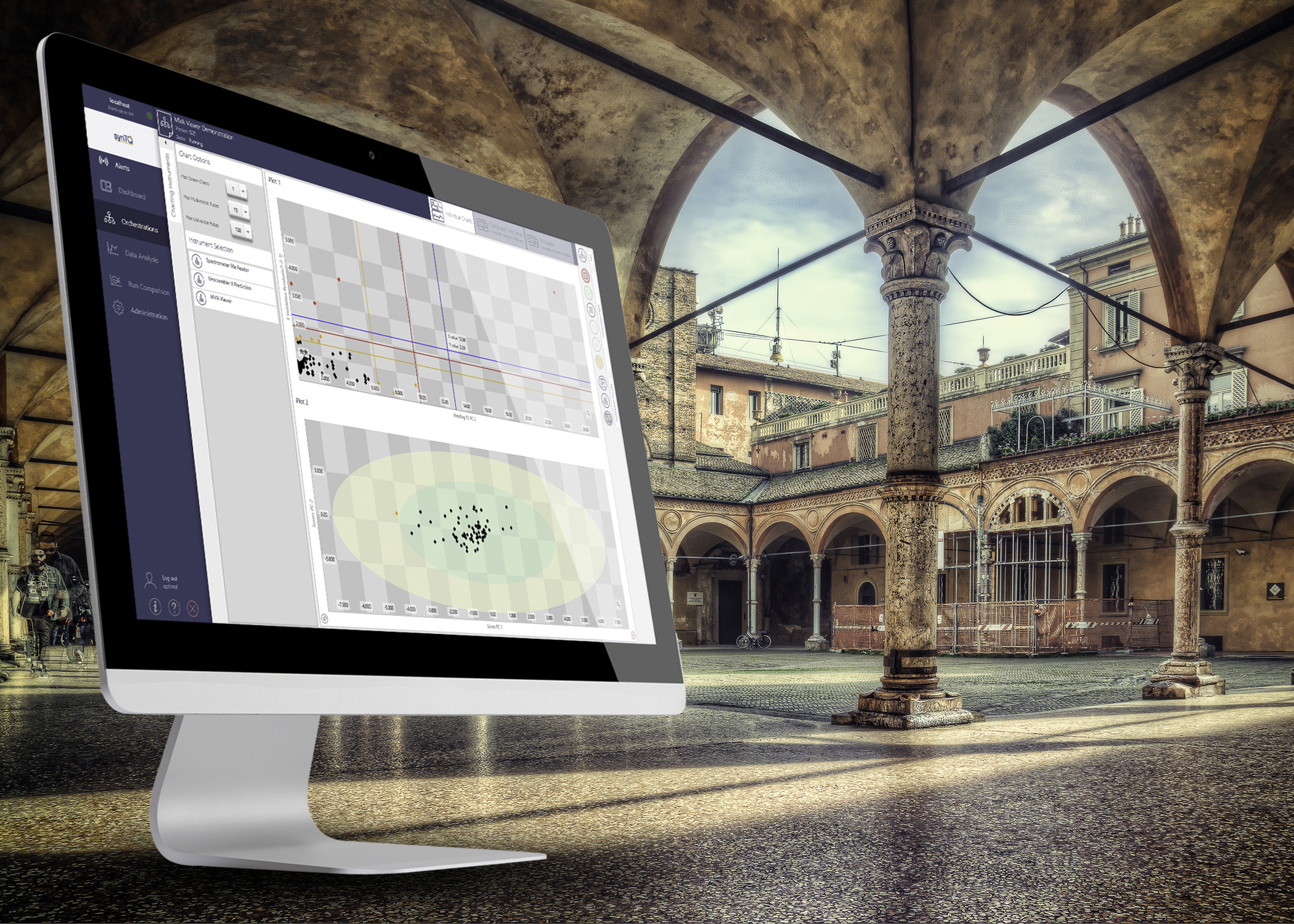

Optimal shows why next-generation materials need PAT at CPAC Rome Workshop 2019 Optimal Industrial Technologies will sponsor and present at the Center for Process Analysis and Control (CPAC) Rome Workshop 2019. The management and applications team will also discuss how its process analytical technology (PAT) knowledge management platform, synTQ, can support the development and manufacture […]

At IFPAC Washington 2019, Optimal Industrial Technologies will showcase (stand 308) the latest developments for its PAT knowledge management platform synTQ, while also delivering two significant presentations. The presentations will explore the infrastructure required to process and store data generated by PAT and how the needs of Industry 4.0 can be met. From its first […]

In the pharmaceutical industry, both branded and generic drug manufacturers could improve speed to market by adopting a continuous process development and manufacturing approach. Process Analytical Technology (PAT) allows pharmaceutical producers to evolve from a batch production process to a continuous one. It therefore represents a key enabling technology that can lead to a better […]

The majority of the top ten global pharmaceutical companies are now working with a PAT based production and development platform set to bring big benefits to the industry. Over half of the top ten global pharmaceutical companies are now using or evaluating the process analytical technology (PAT) based production and development software platform from Optimal. […]

Optimal Industrial Technologies will exhibit its latest synTQ PAT knowledge management platform at the 2018 Annual Meeting of the American Institute of Chemical Engineers (AIChE). There, visitors will be able to learn more about how process analytical technologies (PAT) and live data-driven manufacturing are transforming product development and manufacturing in highly regulated industries. The AIChE […]

One of the key topics at the IFPAC Cortona Conference 2018 will be “Manufacturing Innovation and Global Regulatory Harmonization”. In relation to this subject, Optimal Industrial Technologies will discuss how to address regulatory compliance and cyber security issues when implementing process analytical technologies (PAT) in pharmaceutical manufacturing processes. During the talk, Optimal will also discuss […]

The VIAVI Solutions and IMA Active symposium: “PAT and QbD in the solid dosage manufacturing: NIR integration from an engineering perspective” will run from 23-24 October 2018 at the IMA factory in Bologna, Italy. Optimal Industrial Technologies will deliver a presentation on how process analytical technologies (PAT) and quality by design (QbD) can benefit oral […]

At Proventa International’s Biomanufacturing Strategy Meeting Europe 2018, Optimal Industrial Technologies will present how process analytical technology (PAT) knowledge management platforms such as synTQ, are benefitting biopharmaceutical processes worldwide. Controlling quality in real-time is reducing costs, delivering high-quality products and enabling the shift towards continuous manufacture. Proventa International’s Biomanufacturing Strategy Meeting Europe provides a […]

Starting something new can be daunting, especially if it is big, complicated and important. Process Analytical Technology (PAT) is big and complicated and important; in fact, it looks like it will soon be indispensible for pharmaceutical production. The role of a working structure based around PAT principles is to measure product quality attributes in real […]